Digital Rotational Viscosity Meter

$589.00 USD

Our Rotational Viscosity Meters are designed to precisely determine the viscosity of various fluids, and they are extensively employed in both scientific research and industrial production due to their superior attributes, which include high measurement accuracy, exceptional stability, user-friendly operation, swift responsiveness, and straightforward maintenance.

- Single-point measurements on 3.5” color display

- Viscosity range from 1 mPa.s to 100000 mPa.s

- Equipped with four different types of rotors to measure different samples

- A wide range of measurement modes are available, such as timed measurements, automatic scanning, and equipped with a temperature probe.

Reliable, Traceable Viscosity Results

Our Rotational Viscosity Meters enable accurate measurement of viscosity and help industrial upgrading. Viscosity, as an important physical property inside the fluid, has a crucial impact on the quality and performance of a variety of industrial products, and is an indispensable tool in modern industrial production.

- The instrument adopts reliable mechanical design technology, manufacturing process and microcomputer control technology, and the data acquisition is stable. The display uses a high-resolution3.5-inch IPS display with intuitive data display, and the color screen can directly display viscosity, rotational speed, temperature, percentage torque, rotor number and the maximum measurable viscosity of the selected rotor number at the current rotational speed.

- The instrument has high measurement sensitivity and reliable test results, and is a precision instrument used to measure the absolute viscosity of Newtonian liquids and the apparent relative viscosity of non-Newtonian liquids.

- It is widely used in viscosity measurement of various fluids such as grease, paint, plastic, medicine, food, coating, glue, adhesive, resin, chemical raw materials, etc.

- A wide range of measurement modes are available, such as timed measurements, automatic scanning, and temperature probes are standard on all models。

Key Features

The Easiest-to-use Rotational Viscometer

Setup takes less than three minutes: Package includes an SOP booklet with first steps and straightforward user training. Our rotational viscometers guide you from startup through the entire measurement process via an intuitive user interface.

Equipped with Temperature Probe

Equipped with a temperature PT1000A probe, it can measure the sample temperature range of 0 to 150°C in real time.

Easily Generate & Export QC Data

The device memory can store up to 50 sets of data. In addition, the device can be connected to a computer or printer via USB or RS232 to export or print data in text format.

Multi-mode Measurement, Ultimate Freedom in Gauging

- Standard measurement: stable measurement, automatic stop

- Timed measurement: measurement is set for a specified time, up to 99 minutes

- Auto scan: automatic scan recommends the appropriate rotor speed for you

Reliable Viscosity Tests

A level bubble on top of the unit visually indicates proper leveling, preventing measurement errors and ensuring excellent full scale accuracy of ± 1%. If you need to measure a new formulation, the unit will automatically guide you to the correct spindle/speed configuration using the Auto Scan mode.

Durable Parts, Maximum Uptime

The equipment uses highly durable bearings and can convert kinematic viscosity, your uptime is maximized and ongoing service costs are reduced to a minimum. All of our spindles are made of superior stainless steel , which increases spindle lifetime by protecting them from corrosion.

Four-kind Stainless Steel Rotors

Four different types of stainless steel rotors are provided. Users can replace the rotors according to the predicted viscosity to make the measurement results more accurate.

Measurements and Curves

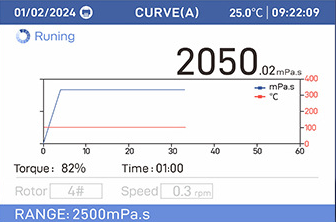

General measurement page

Date time, temperature, prompt, viscosity, torque percentage, measurement time, spindle, speed, current setting maximum range

Curve measurement page

Date time, temperature, prompt, viscosity, viscosity temperature curve, torque percentage, measurement time, spindle, speed, current setting maximum range

Product Specification

| Measurement Range | 1~100000mPa.S |

| Rotation Speed | 6/12/30/60rpm |

| Rotor Specification | Standard 1/2/3/No. 4 (No.0 rotation is optional, low viscosity samples can be measured) |

| Measurement Mode | Fast, timed, automatic scanning |

| Temperature Display | Standard temperature probe |

| Measurement Error | ± 1% FS (Liquid) |

| Measurement Reproducibility | ± 0.5% FS (Liquid) |

| Display Resolution | 0.01mPa.s |

| System Function | General measurement, Linear dispersion measurement, recording, viscosity conversion, printing |

| Language | Switch between Chinese and English (optional English) |

| Measurement Record | 50 articles |

| Interface | USB, RS232 |

| Working Environment | 0℃~40℃, Humidity 20%~ 80% in an air environment without condensate |

| Input Power | 100~240V,50~60HZ |

| Lifting Stroke | 250 mm |

| Product Size | 280x260x395 mm |

| Net Weight | About 5kg |

Stainless Steel Rotors

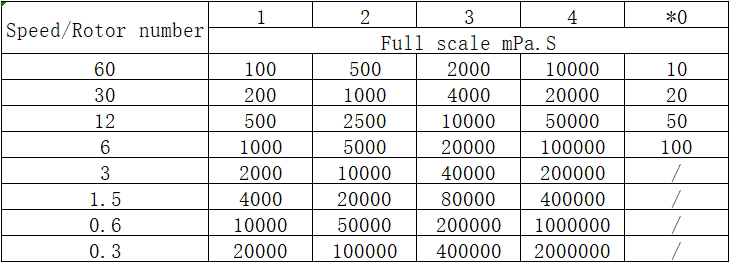

The viscosity range corresponding to the combination of rotor and rotational speed can be referred to the table below.

The items with * are optional

Applications

Various Oils

Paint

Cosmetics

Various Beverages

Ink

Dairy

Package List

- Measuring Cup

- Host Crossbar

- Rotor Protection Frame

- Rotational Viscosity Meter

- Rotors 1-4

- Power Adapter

- Wrench*2

- Lifting Assembly

- Base

- Instruction Manual

- USB Interface

- RS232

FAQ

How does a Rotational Viscosity Meter work?

Our Rotational Viscosity Meters are of the spring type: the rotation of the spindle deflects the spring. An optical sensor detects the deflection and from this the viscosity of the sample is calculated. The test sequence is the following: The user attaches a spindle to the rotational viscometer, sets a speed, and receives the dynamic viscosity and the torque (mostly in %). The resulting driving torque depends on the rotational speed w, the spindle geometry, and the sample viscosity.

Digital reading: The viscosity meter is automatically calculated and displayed on a screen for every spindle/speed combination. There are no further calculations necessary.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.